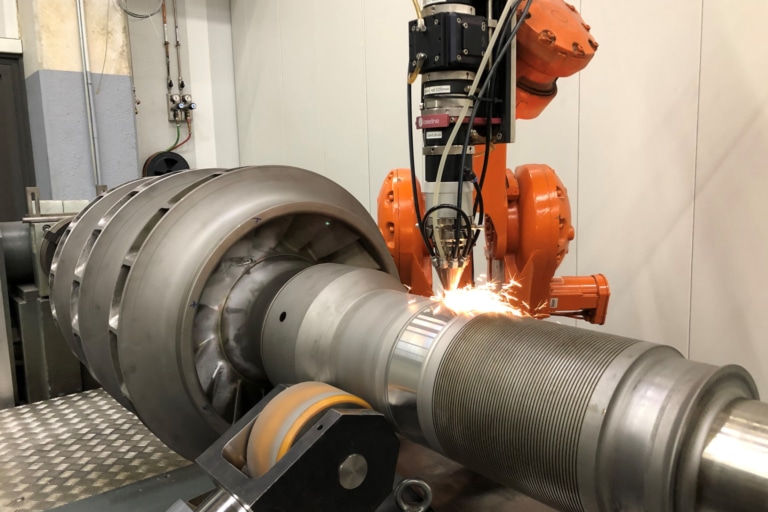

At TMCOMAS we have almost 70 years of experience in mechanical and surface engineering and we are specialists in Laser Cladding.

Laser Cladding is the latest generation of coating technology that helps to improve the life of parts.

The main characteristics of Laser Cladding are:

- Lack of interconnected porosity.

- Very low dilution.

- Very low heat affected zone (zero thermal distortion).

- Strong adhesion (welding).

- Machinable and grindable.

- Refined metallographic structure, improved properties.

- High reproducibility (CNC).

- Laserline FDK VG4L 1000-4000 high power diode laser, 4000W peak power and wavelength from 900 to 1030 nm.

- Two-color optical pyrometer for process control.

- MacroCLAD 45V2 refill nozzle (1500 microns optical fiber).

- Positioning using 4-axis CNC-Cartesian machine.

And the materials we use to make the Laser Cladding coatings are:

- Co

- Ni

- Inox

- Cermets (WC)

For further information:

For further information about LASER CLADDING or about the rest of our services, you can contact us on our site: https://tmcomas.com/en/ or sending us an email at: comercial@tmcomas.com

Send us a message

Apart from Laser Cladding, at TMCOMAS, we are specialists in:

Rotating Machinery Repair

Repair and personalized advice.

Thermal Spray

Pioneers in high-tech coatings.

Babbit Bearings

Manufacturing under drawing or sample and repair of all kind of babbit bearings.

Babbit Bearings

Manufacturing under drawing or sample and repair of all kind of babbit bearings.

FURTHER INFORMATION

Precision Machining

Steels and superalloys high quality machined.

Special Welding

Weldings following procedures and qualifications upon request.

Technical Office

Technical office for reverse engineering office and critical spare parts drawings.

Technical Office

Technical office for reverse engineering office and critical spare parts drawings.

FURTHER INFORMATION

Rotors Storage

Pionniers en revêtements de haute technologie

Av. Estació, 54. 17300 BLANES (SPAIN)

GPS, N 41º 40′ 34.35″, E 2º 46′ 40.12″

CONTACT

Olga Yvanyushina

Sales Engineer

olga@tmcomas.com

00 34 603 426 604